Detailed Product Description

| Power: | 3000W | Production Speed: | 45m/min |

|---|---|---|---|

| Labeling Accuracy: | ±1mm | Label Max Width: | 190mm |

| Weight: | 380KG | Certification: | CE |

| Apply To: | Adhesive Sticker Labeling | Voltage: | 380V / 220V |

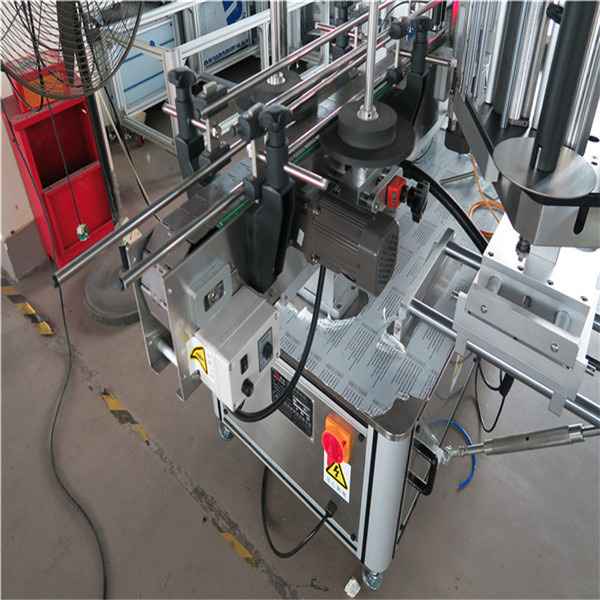

Double Side Sticker Labeling Machine , Automatic Label Applicator Machine

Technical Parameter

| Production speed | 45m/min |

| Labeling accuracy | ±1mm |

| Label max width | 190mm |

| Bottle diameter | Thickness≥30mm height≤500mm |

| Label inner diameter | 76.2mm |

| Label outer diameter | Max330mm |

| Outline size | L3048×W1700×1500mm |

| Weight | 380KG |

| Using power | 380/220V 50HZ 3000W |

Product Characteristic

1 , The machine is designed with large-power and strengthening structure.

2 , The double side automatic labeling machine is suitable for square bottles or flat bottles with double mark or single mark.

3 , The label is pressed by a flap after applying on bottle and is pressed by the active and passive sponge rollers.So when the label is stuck it hasn’t any air bladder. It is especially applicable to the crystal bottles labeled with transparent labels.

4 , The shape belt can be inclined ,and the labeling head can be adjusted at eight orientations ,so the machine can be adjusted successfully in several minutes for any bottle.

5 , The muti channel encoder detects labeling position precisely at high speed

6 , The pressure between the active axle and the press roller can be adjusted ,so the running direction of the label can be adjusted freely . the label is only pressed flexibly without causing any distortion.

7 , The touch screen based human interface in Chinese and English with the online helping system makes it easy for operate the machine for the workers .the press belt is geared into the main transporting line ,so it makes the two transporting lines work in synchronous absolutely .

8 , The labeling head adopts the structure of the double press rollers . it guarantees that the label is pulled tightly but isn't broken because of the underneath paper die-cutting, the separated clutch makes the strain more balanced.

9 , The optional air driving and roller labeling set can label round bottles precisely.

10 , The machine apply the famous server motor, so it realizes real closed loop controlling and it avoids the phenomenon of “the blind man walk” when the machine apply the stepper motor.

Application

1 , The machine is apply to the Daily Chemical and Food Industry.

2 , Labeling max width is 190mm(can be raised according to the require),

3 , Thickness aboutBottle diameteris greater than or equal to 30mm,height is less than or equal to 500mm,

4 , Max outer diameter is 330mm.Label inner diameter is 76.2mm.

Advantages

1 , Most component are made by aluminum, cutting the weight and cutting the transportation fees.

2 , The production max speed is about 45m/min. Labeling accuracy is ±1mm.

3 , The machine’s Using power, dimension, Weight are customized.

Product Details

Tag: auto labeler machine, automated label applicator