Detailed Product Description

| After-sales Service Provided: | Engineers Available To Service Machinery Overseas | Advantage: | Economy Labeling Machine With Good Performance |

|---|---|---|---|

| Labeling Speed: | 60-300pcs/min | Accuracy Of Labeling: | ±0.5mm |

| Business Type: | Manufacturer, Trading Company | Weight Of Labeling Machine: | 150kg |

| Operating Temperature: | 5~35℃ | Operating Humidity: | 30%~80% RH |

| Operating Environment: | No Flammable And Explosive Gas And Dust |

10-50ml round bottle vial labeling machine for lipsticks of cosmetic

Application

This 10-50ml round bottle vial labeling machine for lipsticks of cosmetic isapplicable for all kinds of flat objects such as food, chemical, pharmaceutical, cosmetic, stationery, CD disc, carton, box and various oil kettles etc.This small bottle horizontal labeling machine is made to label all kinds of small round bottles that cannot stand steady, likebeer bottle,soybean oil, andaerosol can.

Specifications

| Name | Vial Labeling Machine |

| Labeling Speed | 60-300pcs/min |

| Height of Label | 20-90mm |

| Length of Label | 25-80mm |

| Accuracy of Labeling | ±0.5mm |

| Power Supply | 220V 50/60HZ 2KW |

| Gas Consumption of Printer | 5Kg/m2(if add coding machine) |

| Size of Labeling Machine | 2500(L)×1250(W)×1750(H)mm |

| Weight of Labeling Machine | 150kg |

| Accessory | Imported step motor or servo motor is used for the labeling head to assure labeling speed and accuracy |

| Material | The machine is made by 3mm SUS304 stainless steel and high quality aluminum alloy |

| Configuration | The photo electricity and control system apply advanced component from Germany or Japan or Taiwan |

| Flexibility | Client can chose to add printer and code machine; can chose to connect with converyer or not. |

Competitive Advantage

1. Synchronization chain mechanism ensure labeling smooth and precise calibration

2. Adopt mature technology PLC control system, operation is stable and high-speed.

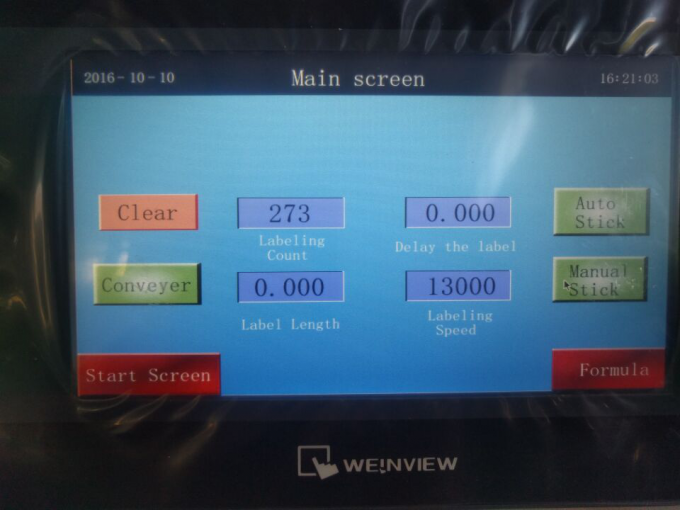

3. Using touch-screen control operating system, simple and efficient.

4. Imported electric elements, stable performance, low failure rate.

5. No bucket no labeling, automatic alarm when achieve leakage label.

Main usage and capacity:

This labeling machine is equipped with computer touch -screen which layout very large scale integrated circuit .it is controlled by micro-computer with Chinese character touch screen, realized the man-machine communication .Micro-computer configuration is helpful for all data input by touch screen and also for all-round control the running condition once machine started.

PLC horizontal adhesive labeling machine is the upgrade product of out company which have simple and reasonable structure and easy for operation .The production can be adjusted by the specification and feature of bottles and labels .it's fit for all kinds of bottles .Both transparent adhesive sticker and non-transparent adhesive sticker can be well labeled on the bottles or containers whatever are glass bottles or plastic bottles which used in food, machine or cosmetic and Various types of glass and plastic bottles.

Instruction of Control System:

Control Panel and function:

Running Interface: System operation interface is the machine to work normally to display the interface. Start: control the conveyor belt, press the conveyor belt to start, then click the conveyor belt to stop;

Under system running interface:

Supervisory control:

Out Label Length: pulls the label servo delay to stop

Outgoing label delay: Pulls the label servo delay time to start

Out of the standard count: that a label, the cumulative measurement up (power to zero)

Out of standard speed: the speed of the tag label servo (servo motor speed)

Clear: Clear the label count

Labeling: press the machine after the start their own labeling

Measure the label: When reloading paper, hold down the measurement key, manual out of a standard (test the length of the subject)

Tag: vial sticker labeling machine, small bottle labeling machine