Detailed Product Description

| Label Speed: | 60-350pcs/min(Depending On The Length Of Label And Thickness Of Bottle) | Thickly Label Object: | 20-120mm |

|---|---|---|---|

| Power Supply: | 220V 50/60HZ 3.5KW Single-phase | Weight Of Machine: | 450kg |

| Key Word: | Self Adhesive Label Printing Machine |

self adhesive label printing machine with single or double sides,110/220V 1.5H label sticking machine for square objects

Application:

Self adhesive label printing machine with single or double sides,110/220V 1.5H label sticking machine for square objects is suitable forall kinds of regular and irregular containerssuch as food, chemical, pharmaceutical, cosmetic, stationery, carton, box and various oil bottleetc.

Technical Parameters:

| Voltage | single phase AC 220v, 50/60Hz |

| Ratio power | 2kw |

| Labeling speed | MAX 200pcs/min (according to the bottle size and label size.) |

| Precision of labeling | ±1mm |

| Available region of labeling: height | Height10-180mm, length 10-300mm |

| Max labeling provided | diameter 380mm, inner diameter of paper ring76mm |

Configuration:

| No. | part | brand | quantity |

| 1 | PLC | MITSUBISHI(Japan) | 1 |

| 2 | Main converter | DANFOSS(Denmark) | 1 |

| 3 | HMI | WEINVIEW(Taiwan) | 1 |

| 4 | Servo labeling motor | DELTA(Taiwan) | 2 |

| 5 | Servo labeling motor driver | DELTA(Taiwan) | 2 |

| 6 | Conveyor motor | H.Y(Taiwan) | 1 |

| 7 | Conveyor motor gearbox | H.Y(Taiwan) | 1 |

| 8 | Label feeding motor | GPG(Taiwan) | 2 |

| 9 | Label feeding motor gear box | GPG(Taiwan) | 2 |

| 10 | Paper receiving motor | GPG(Taiwan) | 2 |

| 11 | Paper receiving motor gear box | GPG(Taiwan) | 2 |

| 12 | Bottle separating motor | GPG(Taiwan) | 2 |

| 13 | Bottle separating motor gear box | GPG(Taiwan) | 2 |

| 14 | Bottle separating frequency convertor | DELTA(Taiwan) | 1 |

| 15 | object detect magic eye | OMRON(Japan) | 1 |

| 16 | optical fiber | OMRON(Japan) | 1 |

| 17 | Label feeding magic eye | OMRON(Japan) | 1 |

| 18 | paper receiving magic eye | OMRON(Japan) | 1 |

| 19 | No label alarm magic eye | OMRON(Japan) | 2 |

| 20 | Label outing detect magic eye | LEUZE(Germany) | 2 |

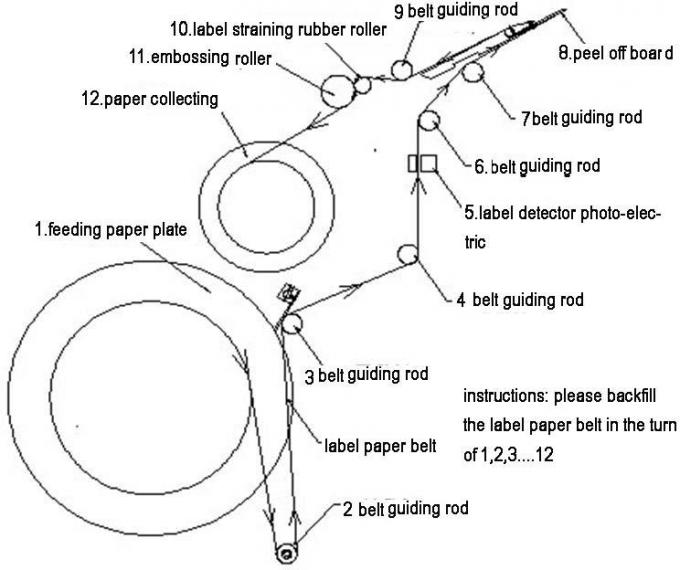

Feeding in labels

1. Check and confirm the frontal side and reverse side.

2. Move the guiding ring to a proper position.

3. Cincture the labels paper belt according to routing in the indicated picture.

4. Strain out the labels and make sure the label paper belt is smooth.

5. Fix the end of the label paper band on the paper collecting plate.

6. Push the upside guide ring until it is at the same level with the label edge.

7. After cincturing the label paper band, please lock the label outputting/collecting pressure wheel. Then press the labeling button, manually check the working piece then you will get label output. It is automatic for controller to calculate the exact labeling length and clearance, you can adjust the position and length of labeling output position by way of adjusting the labeling output photoelectric detector.

Tag: bottle sticker labeling machine, automatic label applicator machine