Detailed Product Description

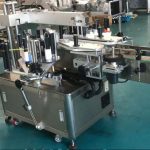

| Size Of Machine: | 2800(L)×1450(W)×1360(H)mm | Product Rate: | 60-200 Products Per Minute |

|---|---|---|---|

| Minimum Label Size: | 15*20mm | Maximum Label Size: | 200*280mm |

| Height Of Object: | 30-280mm | Thickness Of Object: | 20-200mm |

Square bottle double side horizontal labeling machine regular or irregular container

Quick Details:

Automatic Grade: Automatic

Driven Type: Electric

Power Supply: 220V 3.5KW Single-phase 50/60HZ

Height of Object: 30-350mm

Applicable Diameter of Bottle Body: 20-120mm

Height of Label: 5-180mm

Place of Origin: Shanghai,China(Mainland)

Size of Labeling Machine: 2800(L)×1650(W)×1500(H)mm

Weight: 450Kg

Label roller outside diameter: 420mm

After-sales Service: Provided engineers available to service machinery overseas

Labeling Speed: 60-350bottles/min

Application:

The labeling Machine is suitable for all kinds of regular and irregular containers, flat surface or round bottles, especially ideal for flat surface and square containers.

Competitive Advantage:

1. After test the machine for you,we will send the whole machine by ship or other ways you want, which means you even have no need to reassemble the machine, just move to the factory, and press the switch button, it will work well.

2. We have professional English/Spanish/Japanese/Korean/Portuguese/French salesman, if any problem after you received you machine, we will go through with you all the time.

Part operational manual

1. the sensitive detector (label detector)

(1). Move the detector to the label blank place, press the black button longer time, you can see the green and yellow light flickering at the same time. Loose the button. When flicking about 5 seconds, press the black button short time, now the indication light is not flicking. Move the detector to the label blank place, the yellow light “on”, leave the blank place the yellow light “off”. The sensibility adjustment is finished.

(2). Move the detector to the label blank place, press the black button longer time, you can see the green and yellow light flickering at the same time. Loose the button. When flick about 5 seconds, press the black button short time, now the indication light is not flicking. Move the detector to the label blank place, the yellow light “on”, leave the blank place the yellow light “off”. The sensibility adjustment is finished.

(3). If it still does not work well, repeat it until it works normally.

Tag: automatic label applicator machine, automatic bottle labeling machine