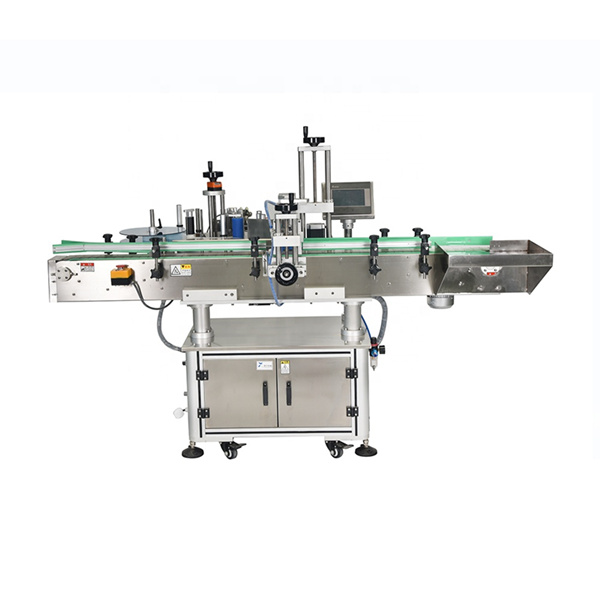

Detailed Product Description

| Device Advantages: | Servo Motors | Item: | Three Labels Labeler Machine |

|---|---|---|---|

| Label Inner Diameter: | 76.2mm | Label Outer Diameter: | 400mm |

| Main Material: | Aluminum | Function Added: | Fold Label |

| Suitable Samples: | Three Labels On One Bottle | Speed: | 5000-10000B/H |

Automatic self-adhesive Front & Back & Neck Labeling System

Suitable for

1, The labeling system to effectively apply labels to the front and back of a variety of container shapes at speeds up to 160 containers per minute. Also required was the ability to apply a label to the neck of these containers.

2, Neck ,front ,back labels in different labels reel

3, Speed 5000-10000B/H up to bottle and label size

4, The labeling machine with three sets labeling head

Technical Parameter

| Production speed | 5000-10000B/H |

| Labeling accuracy | ±1mm |

| Label max width | Neck label125mm front back label195mm |

| Bottle diameter | 30-110mm |

| Label inner diameter | 76.2mm |

| Label outer diameter | 330mm |

| Outline size | L4080 W1200×1600mm |

| Weight | 650KG |

| Using power | 380V/220V 50Hz 6500W |

| Conveyor height | 950mm |

Advantages

1 , Machine-wide adoption of a mature technology PLC control system, so that the whole stable, high-speed

2 , Operating system using touch-screen control, simple, practical, efficient

3 , The advanced technology of printer code machine, so that the writing clear, fast and stable

4 , The upgraded three-dimensional butterfly designed station, the angle of the labeling can be adjusted, adapt to the separate bottles

5 , Using top hold belt device, make bottle more stable and imporve labeling accuracy

6 , Synchronization chain agencies, to ensure calibrate stably and accurately

7 , Labeling transparent label without bubble, self-adhesive label without wrinkle

8 , The large scope of application, a multi-function machine and high adaptable

9 , The type of machine can install special institution,realize neck label wrap aound labeling,front and back labels for square, flat bottle at one finish.

10 , The eight dimension adjustment with the new type lebeling head, for special angle products, only need to adjust angle, easy operation and convenient.

11, Our machineries used servo motor from famous factory,they can realize the closed loop control to avoid the general stepping motor the blind phenomenon, high precision subdivision, built in absolute value encoder all this in order to provide high accuracy.

12 , Most component are made by aluminum,cutting the weight and cutting the transportation fees.

Description

1 , Coder printer ,laser ,bottling turntable ,connectorbetween labeling machine and othermachine for options

2 , The servo motor system.

3 , Clutch design, make the label tension force more stable, and easy to improve labeling precision.

4 , Machine structure is simple, easy to operation and maintenance.

5 , Advanced color man-machine interface control system.

6 , Germany Siemens PLC control, high reliability.

7 , Used Germany, Japan inductors.

8 , Neck, front, back labels of round bottles would be suited for. front / back labeling for square ,flat ,cone bottels /jar / containers

10 , Added Function:With the special bottles added fold top label,also could be finished.

11 , While it has some problems with the labels, running or broken, the pressure between the driving shaft and roller would adjustable, the direction can be adjusted arbitrarily,rather than the ordinary elastic pressing.

12 , The labeling head use double compression rollers structure,ensure that the label paper tension and avoid the label break off phenomenon because of back paper cutting injury, sectional type clutch makes tension more balanced.

Others

1 , Touch Screen Control System with 20 sets Job Memory

2 , Labeling speed up to 200BPM ( according to the length of label )

3 , Simple Straight Forward Operator Controls

4 , Special design for three-side labeling,also added fold label.

Tag: self adhesive sticker labeling machine, self adhesive labeler