Detailed Product Description

| Size Of Machine: | 2800(L)×1450(W)×1360(H)mm | Height Of Object: | 30-280mm |

|---|---|---|---|

| Thickness Of Object: | 20-200mm | Height Of Label: | 5-150mm |

| Length Of Label: | 25-300mm | Accuracy Of Labeling: | ±1mm |

| Label Roller: | With Carton Center | Labeling Speed: | 60-200pcs/min |

| Main Converter: | DANFOSS | Servo Labeling Motor: | DELTA |

| Conveyor Motor: | H.Y | Spoke Motor: | GPG |

SUS304 cabinet two sides sticker labeling machine with personal care products for square bottle

Features:

1. High accuracy of labeling, the acuities of label head to tail connect local just reache + / - 0.5 mm

2. Machine can be supplied with Optional Toughened (Tampered) Glass or Acrylic Safety Cabinet. Machines having required all basic features as a standard fitment to match the current MARKET needs and also saves cost and time.

3. Putting the bottle to orientation part by manual and fix the bottle;

4. This very affordable applicator provides a reliable, industrial grade labeling system that is very simple to operate. Its design and operation draws on over 30 years of dedicated label dispenser experience.

Techinical parameter:

| Type | Labeling machine |

| Condition | New |

| Packaging Type | Case |

| Packaging Material | Wood |

| Automatic Grade | Automatic |

| Driven Type | Electric |

| Power Supply | 220V 3.5KW 50/60HZ |

| Size of Machine | 2800(L)×1650(W)×1500(H)mm |

| Speed | 60-350pcs/min(relate to materials and labels'size) |

| Height of Object | 30-350mm |

| Diameter of object | 20-120mm |

| Height of Label | 5-180mm |

| Length of Label | 25-300mm |

| Accuracy of Labeling | ±1mm (excluding the error of bottle and label) |

| Can choose different types of sending label module according to clients' higher requirement for labeling speed and precision. | |

Configuration:

| No. | part | brand | quantity |

| 1 | PLC | MITSUBISHI(Japan) | 1 |

| 2 | Main converter | DANFOSS(Denmark) | 1 |

| 3 | Bottle separating frequency convertor | DELTA(Taiwan) | 1 |

| 4 | HMI | WEINVIEW(Taiwan) | 1 |

| 5 | Servo labeling motor | DELTA(Taiwan) | 2 |

| 6 | Servo labeling motor driver | DELTA(Taiwan) | 2 |

| 7 | Conveyor motor | H.Y(Taiwan) | 1 |

| 8 | Conveyor motor gearbox | H.Y(Taiwan) | 1 |

| 9 | Spoke motor | GPG(Taiwan) | 1 |

| 10 | Spoke motor gearbox | GPG(Taiwan) | 1 |

| 11 | Bottle separating motor | GPG(Taiwan) | 2 |

| 12 | Bottle separating motor gear box | GPG(Taiwan) | 2 |

| 13 | object detect magic eye | OMRON(Japan) | 1 |

| 14 | optical fiber | OMRON(Japan) | 1 |

| 15 | Powder | DELTA(Taiwan) | 1 |

| 16 | No label alarm magic eye | OMRON(Japan) | 2 |

| 17 | Label outing detect magic eye | LEUZE(Germany) | 2 |

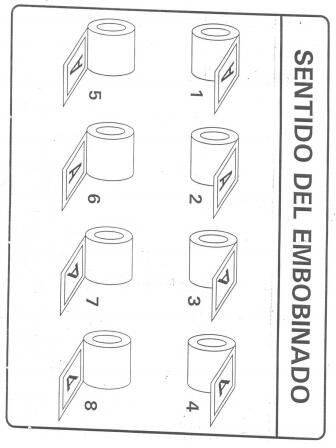

the direction of labeling:

1. two sides of labeling machine with coding machine

The direction of labeling without coding machineis clockwise.

The direction of labeling with coding machine is counterclockwise.

There are two sides of labeling machine with two label head. They can sticker the front and back.

The diagram is as beblow.

Tag: bottle sticker labeling machine, automatic label applicator machine