Detailed Product Description

| Product Of Material: | Most Aluminum And Stainless Stee | Place: | Shanghai,China |

|---|---|---|---|

| Bottle Application: | Plastic,Glass | Speed: | 250BS/Min |

| Accuracy: | 1mm | Power: | 6500W |

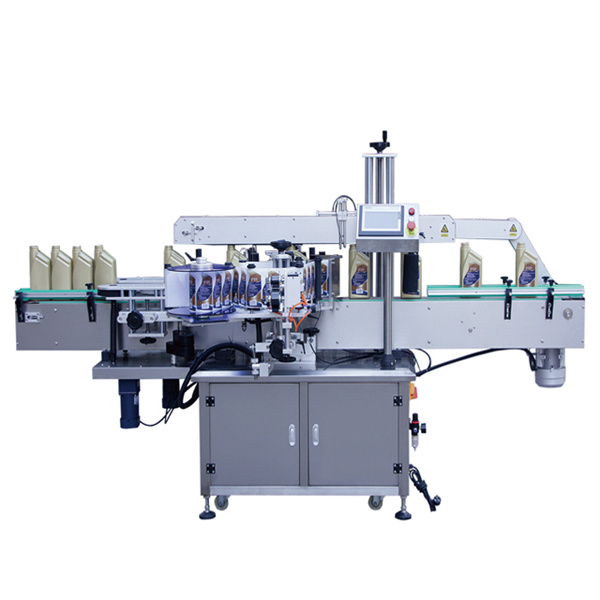

Automatic Adhesive glass bottle labeling machine to do the Front and neck

Application

This machine is single side double labels labeling machine, suitable for flat bottle,square bottle,round bottle same side with two labels’ labeling

Can quickly switch to a different size bottle, simple to cooperate,orderliness beautiful, clean, easy to wash

Applicable to all industries suitable for two labels aline on same side position labeling , such as daily chemicals, petroleum, machine oil, cleaning supplies, food and beverage, pharmaceutical and so on.

New design labeling head: using VKPAK patent design of new concept, increase strong rigidity making, multi-dimensional adjustment

Transport sector: Taiwan imported AC motor 1500W, Danfoss frequency converter adjust the speed

Guide Bottle institution: double coordinates adjusted scratch check rails in SS.

Bottle dividing institution: Panasonic Motor,frequency control of motor speed.

New style patent synchronous chain correcting institution: Panasonic motor, frequency converter adjust the speed , synchronous with the conveyor. (specially widely suit for cone bottle’s correcting,strength making,and suit for large range bottle)

Top belt holder Pressing institution: spiral bevel gear transmission, synchronized with the conveyor institution

Scratch label institution: sponge spring steel plate combination, Teflon patch.

Pressure label institution 1: Combination non-power roller, quickly removable to accommodate different sizes of labels.

Large rubber roll institution : use 70% hardness large rubber roller constructure, motor control

Machine design is reasonable strong rigidity

Technical Parameter

| Production speed | 250BS/min |

| Labeling accuracy | ±1mm |

| Label max width | Neck label125mm front back label195mm |

| Bottle diameter | Thickness≥30mm Height≤500mm |

| Label inner diameter | 76.2mm |

| Label outer diameter | 400mm |

| Outline size | L4080 W1200×1600mm |

| Weight | 650KG |

| Using power | 380V/220V 50Hz 6500W |

VK-675G performance comparison between the labeling machine and others

1) The labeling machine use ultra-small inertia servo motor, but most of the labeling machine still use the stepper motor

2) The machine with PLC control, rather than general SCM

3) The HMI of the machine is a real sense of the digital control, rather than simply display

Transport sector: imported AC motor, Frequency converter speed regulation

Ultra-high-power AC motor, with a large capacity inverter, the speed of sending bottles more stable, which will help improve the labeling accuracy;

In the labeling process of the machine, position of the optical switch for measured object can be adjustable to achieve zero-latency, so the machine can achieve zero pitch labeling, and improve greatly the production speed, in the past, most of labeling machine ,measured Optoelectronic switch was Fixed, using delayed control, that is, when measured Optoelectronic switch give the signal, the system delays the label, but if in the process, the system voltage changes, or changes in the load conveyor, then the position of label Will have a significant deviations

labeling institution

Labeling machine head octuple space adjustment, the angle can be adjusted freely, easy to paste a variety of difficult and transparent label; high elastic sponge scraper and non-powered round extrusion, to ensure that no air bubbles; mechanical structure of machine uses an enhanced rigid design , Simple, generous and stable.

Tag: glass jar labeling machine, small bottle labeling machine