Detailed Product Description

| Motor Type: | Server Motor | Trademark: | Boson |

|---|---|---|---|

| Transport Package: | Woodcase Inner With PE Film | Specification: | L2000×W700×1400mm |

| Label Roll Core: | 76.2mm | Label Roll Diameter: | 330mm |

Wine / Beer Bottle Label Applicator , Automatic Labeler Machine

Features

1 , It is convenient and intuitive.The two electric control system is controlled by PLC, touch operation interface in English.

2 , When labels remain 200pcs, it can automatic alarm promptly and running out of labels automatically alarm and shutdown.

3 , It has the function of memory stored program, which can store 30 groups of parameters and can be named for different programs. If you need replace different specifications or use different production capacity, it just simply adjust the different parameters, no need to adjust again, greatly improve the work efficiency.

4 , It's not affected by surface color, reflective height inequality, thus ensuring stable stick mark, and without mistake.With the method of correlation electric eye, which can ensure the stability of the detected objects.

5 , Conveyor belt, bottle opener, positioning rotation mechanism adopts adjustable motor drive alone. The labeling head can be adjusted for multi-direction, just convenient operation.

6 , Label position and the stop lever can be adjusted based on the size of posted content, to adapt to a variety of product labeling in the same machine.

7 , To ensure all functions stable and reliable.All system control components are all inspected by incoming inspection test strictly.

8 , All accessories including cabinets, conveyor belt, lever block, and even small screws are all made by stainless steel or aluminum materials, never rust, no pollution to ensure compliance with environmental requirements.

Description

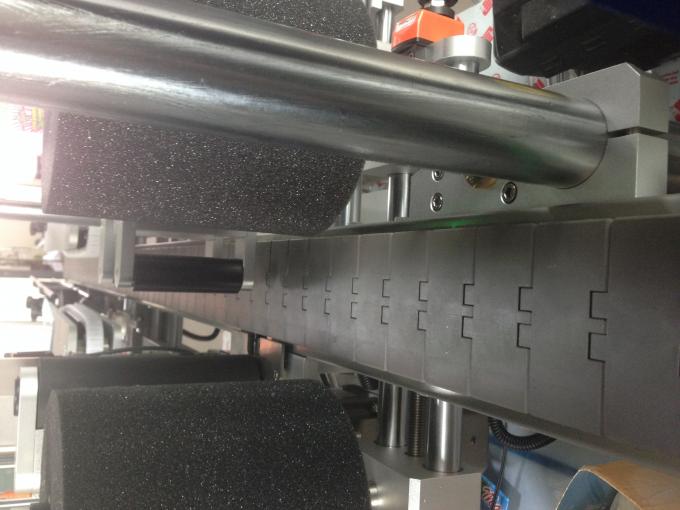

1 , Heavy-duty construction utilizes oversized drive components combined with an aluminum and stainless steel base frame for years of dependable service.

2 , Designed for the application of front and/or back panel labels with the capability to label containers that are round, square, oval or rectangular.

3 , Various product infeed systems are available that provide precise product spacing and orientation. It can be used stand alone or integrated in-line and matching filling equipment speeds.

4 , Advanced high torque micro-stepping driven applicators include ratio-offset and speed-following capability for accurate and reliable application of a wide variety of label materials.

Useage

1, Round bottle labeling is suitable for pharmaceutical, food, cosmetic and other industries, can be attached to the whole week and half circle labeling labeling.

2 , Optional automatic turntable machine, can be directly connected to the front end of the production line, automatic feeding bottle into the labeling machine, increase efficiency.

Working principle

1 , The control system is provided with a control system to send out the label and attach to the product to be in the position of the label, the product flows through the marking device, the marking belt drives the product to rotate, the label is rolled and a label attached to the action is completed.

2 , The core work principle: the bottle body will be separated from the product, the sensor detects the product passed, the signal back to the label control system, in the appropriate place.

3 , Operation process: put the product (can be connected line) - > product delivery (equipment automatically realized) - > product range - > Product Detection - Labeling - > cover label - collection has been labeling products.

Scope of application

1 , Applicable labels: self adhesive labels, adhesive film, electronic regulatory code, bar code, etc..

2 , Applicable products: products that require a label or film on the circumferential surface.

3 , Application industry: widely used in food, medicine, cosmetics, daily chemical, electronic, metal, plastic and other industries.

4 , Application examples: PET round bottle labeling, plastic bottle labeling, food cans, etc..

Service

1 , Range experienced senior engineer come to client company for installation .

2 , If quality problems arise, the supplier provide technical support and timely supply wearing parts.

3 , Supply systematic operation training for client workers.

4 , After client use the machine for several years, we can provide a detailed refurbishment program, the original equipment and replacement of hardware and software upgrades, extend machine service life for more than 3-4 years.

5 , Guarantees all equipment (except human factors) within one year, lifetime maintenance sevices.

Apply to

1 , Label inner diameter is 76.2mm,max outer diameter is 330mm.

2 , The machine is apply to the Daily Chemical and Food Industry,

3 , Labeling max width is 190mm (can be raised according to the require).

4 , Bottle diameter of Thickness is greater than or equal to 30mm,height is less than or equal to 500mm.

Technical Parameters

| Production speed | 45m/min |

| Labeling accuracy | ±1mm |

| Label max width | 190mm(can be raised according to the require) |

| Bottle diameter | Thickness≥30mm height≤500mm |

| Label inner diameter | 76.2mm |

| Label outer diameter | Max330mm |

| Outline size | L2000×W700×1400mm |

| Weight | 380KG |

| Using power | 220V 50HZ 1500W |

Advantages

1 , Most component are made by aluminumofanodizing 3.0 side board, cutting the weight and cutting the transportation fees.

2 , The production max speed is about 45m/min. Labeling accuracy is ±1mm.

3 , The machine’s Using power,dimension,Weight are customized.

Details

Tag: bottle labeling machinery, bottle labeler machine