Detailed Product Description

| Object Diameter: | Thickness≥30mm Height≤500mm | Label Roll: | Inner Diameter/Outer Diameter |

|---|---|---|---|

| Operation System: | PLC Control | Precision: | ±1mm |

| Label Inner Diameter: | 76.2mm | Maximum Labeling Diameter: | 330mm |

Multiple Types Bottle Sticker Labeling Machine PLC Control System

FQA

Q1 , What machines can you produce?

We can produce all kinds of bottles / jars filling machines, sealing machines, capping machines, labeling machines,etc., we can also connect our machines to be various automatic production lines.

Q2 , What materials of your machines are made of ?

According to our clients' different requests, our machines are made of high class stainless steel 304, stainless steel 316 or 316 L, carbon steel, Al alloy, etc.

Q3 , What brands of the electronics and pneumatic parts your machines adopt?

According to our clients' different requests, we can use both domestic brands, joint venture brands and world famous brands.

Q4 , What power voltage do your machines work with?

Usually, our machines work with AC220V 1 phase, 50/60Hz, or AC380V 3 phases, 50/60Hz. We can also make our machines with special voltages, such as, AC 110V, AC415V, etc. So, pase tell us, what is the exact power voltage available in your city before you purchase our machines.

Q5 , Do your machines work with compressed air?

Yes, some of our machines have to work with compressed air, the standard is, 0.6MPa to 0.8 MPa, consumption is various from 0.2 to 0.45 CBM per minute depends on the sizes of the machines. Usually, the users have to prepare an air compressor by themselves in their workshop.

Q6 , What price terms your company can offer?

Usually, we offer EXW or EX-Factory price, we can also offer FOB, CNF or CIF price.

Q7 , What payment term your company accepts?

Usually, we accept T/T or in cash, 40% of the total payment as prepayment / deposit, the remaining 60% will be paid off before we deliver the machines.

Q8 , How long it will take if I put an order of your machines?

The delivery date depends on the sizes and complexity of the machines you order, various from 5 to 50 working days after we receive the prepayment / deposit from our clients.

Q9 , How do you pack your machines before transport / shipping?

Firstly, we clean the machines with anti-rust oil / grease, then, we wrap the machines with anti-moisture plastic film tightly, finally, we pack the machines with solid wood or timber cases that suitable for long distance or sea way transportation.

Q10 , Do you provide the maintenance service?

Yes, we provide maintenance services, because regional difference, we can provide you the services by Email, telephone, express or internet online tools.

Q11 , Is there a warranty and which period of validity does it cover?

We provide one year warranty for all of our machines, the validity time is from the day on which the machines leave our factory to your factory in one year.

Q12 , If any part of the machines broken, how we can get the new replacements?

During the warranty period, if any part broken because of the quality defect or unqualified process, we will send the new replacements to you at our expense. If it exceeds the warranty period, or caused by users' unreasonable operations, or irresistible factors, or any change unauthorized by our company, the clients will have to pay for the new replacements.

Q13 , Is there a specialist to check and test in your factory? On which terms will he be able to start up the equipment in our factory in our country?

Yes, we have specialists to test and check the machines carefully, ensure the machines are at the best state before we transport them to our users. We can send our technicians to your factory to perform commissioning and training your workers. Your company will afford the round air tickets, hotel and foods charges and other necessary charges when our technicians in your city. If our techncians stay more than 5 days, your company will have to pay USD $80 to our technicians each day each person.

And, when the machines are completed,our clients can also send their workers or technicians to our factory to check the machines and learn how to operate the machines.

After sale

1 , Range experienced senior engineer come to client company for installation .

2 , Supply systematic operation training for client workers.

3 , Guarantees all equipment (except human factors) within one year, lifetime maintenance sevices.

4 , After client use the machine for several years, we can provide a detailed refurbishment program, the original equipment and replacement of hardware and software upgrades, extend machine service life for more than 3-4 years.

5 , If quality problems arise, the supplier provide technical support and timely supply wearing parts.

FEATURES

1 , Common diverter is suitable for different diameter of bottles, fast adjustment and locked location.

2 , Coding Machine for option, it can print date, lot No. online.

3 , Structure designed simple, smart, easy to maintenance.

4 , Labeling speed, convey speed, diverter speed can be adjusted.

5 , Use famous brand motor driven, label supply stable and reliable.

6 , PLC control system, the whole machine work stable with high speed.

7 , Photoswitch inspection to ensure no bottle, no labeling; no label, autocorrection and alarm.

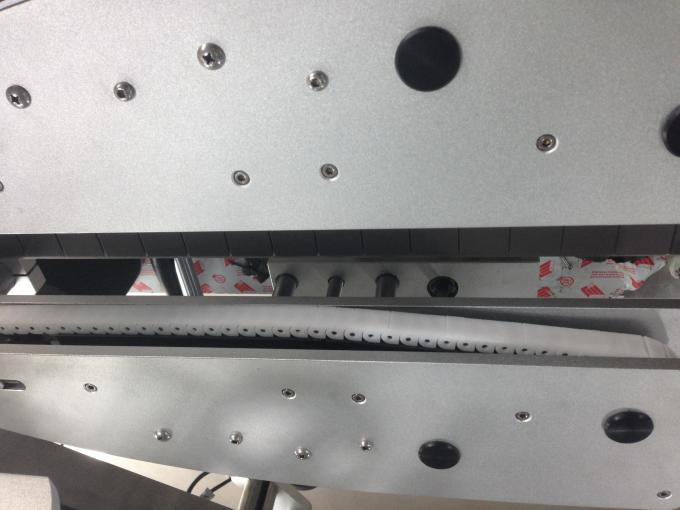

8 , Use resilience cotton belt ensure labeling smooth, no fold, improved labeling quality.

Application

1 , Label inner diameter is 76.2mm,max outer diameter is 330mm.

2 ,The machine is apply to the Daily Chemical and Food Industry,

3 ,Labeling max width is 190mm(can be raised according to the require).

4 , Bottle diameter of Thickness is greater than or equal to 30mm,height is less than or equal to 500mm.

Technical Parameters

| Production speed | 45m/min |

| Labeling accuracy | ±1mm |

| Label max width | 190mm(can be raised according to the require) |

| Bottle diameter | Thickness≥30mm height≤500mm |

| Label inner diameter | 76.2mm |

| Label outer diameter | Max330mm |

| Outline size | L2000×W700×1400mm |

| Weight | 380KG |

| Using power | 220V 50HZ 1500W |

Advantages

1 , Most component are made by aluminumofanodizing3.0 side board,cutting the weight and cutting the transportation fees.

2 , The production max speed is about 45m/min.Labeling accuracy is ±1mm.

3 , The machine’s Using power,dimension,Weight are customized.

Details

Tag: automatic labeler machine, bottle labeling machinery